Insulating glass is a glass product with mature materials and production technology. Its product quality is guaranteed and it is widely used in buildings. Due to problems in the management of individual insulating glass manufacturers, especially in the selection of materials, production process control and construction, there are problems in the quality of their products, the most common is the condensation of insulating glass. What is the reason for the condensation of insulating glass?

1、Insulating glass dew point

The dew point of insulating glass is the temperature at which condensation occurs when the humidity of the gas in the spacer layer of insulating glass reaches saturation. That is, the higher the water vapor content, the higher the glass dew point temperature. The dew condensation phenomenon usually occurs when the temperature of the inner surface of the glass is lower than the dew point of the air in the spacer layer, and the water vapor in the air will condense on the inner surface of the glass.

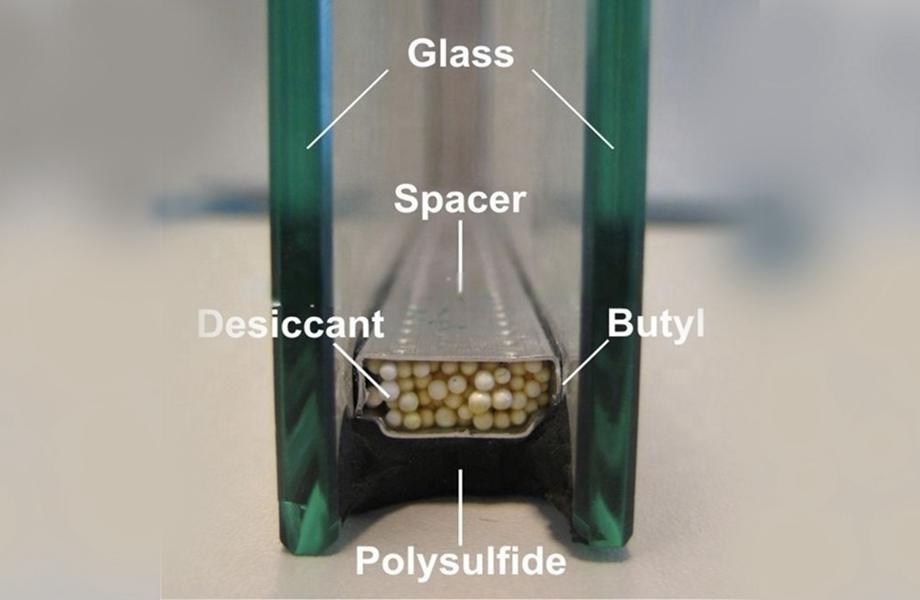

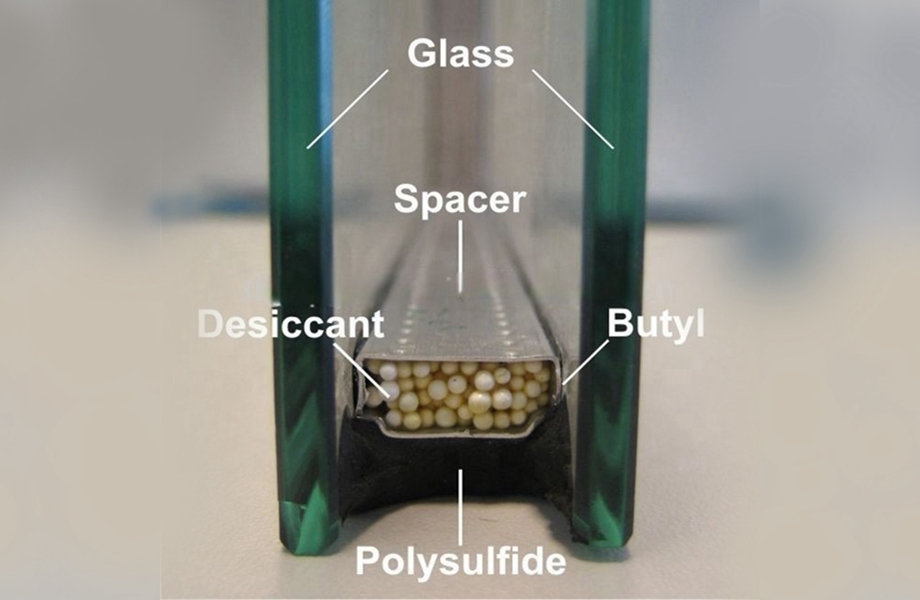

2、The influence of edge sealing materials on the condensation of insulating glass

The side sealing material is mainly butyl sealant of inner sealant and silicone sealant of the outer channel sealant, polysulfide sealant. Its main function is to bond various materials that make up the insulating glass, making it a whole And it has the function of preventing water vapor and other gases from entering the insulating glass spacer. Therefore, as the hollow glass protection structure of the two sealants, the quality of its good or bad determines the overall quality of the hollow glass and whether the phenomenon of condensation.

3、The influence of spacing materials on the fogging and condensation of insulating glass

The spacer materials mainly include: aluminum spacer, stainless steel spacer, composite material spacer, etc. Spacer strips function to carry desiccant, fit seal and overall structural strength. Whether the pore air permeability of the spacer is excellent directly affects the working ability of the desiccant, and whether the working ability of the desiccant is excellent affects whether the insulating glass will be fogged and condensed.

4、The influence of desiccant on the condensation of insulating glass

The function of the desiccant is to absorb the water vapor in the insulating glass spacer, not only absorb the initial water vapor when the insulating glass is produced, but also absorb the water vapor that continuously penetrates into the insulating glass spacer during the use of the insulating glass,so that the gas in the spacer layer remains dry, to ensure that the insulating glass in service, always ensure that the dew point meets the requirements.

5. The influence of production process on the condensation of insulating glass

In the production of insulating glass, the float glass sheet is not cleaned thoroughly, sweat stains, water stains and residual water droplets are stuck on the surface of the float glass sheet; the temperature and humidity control of the production environment is not strict, and it is not dry enough; the bending equipment during frame making causes the back of the spacer cracks, uneven surface of spacer strips in contact with butyl sealant, etc., will all become hidden dangers of dew condensation on insulating glass.

There is also the depth of the external sealant coating is not enough, the mixing effect of the double component sealant is not good, does not meet the requirements of the national standard of "insulating glass" will cause hollow glass condensation.

Through the above analysis, it can be seen that there are many factors causing hollow glass condensation. In the actual production and application, the cause of hollow glass condensation may be either a factor or the superposition of multiple factors.

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.jpg)

.jpg)