Curved PVB laminated glass is a specialized type of glass that combines the benefits of curved glass with the safety features of PVB (Polyvinyl Butyral) interlayers. This glass is produced by permanently bonding two or more layers of bent glass together with a flexible interlayer. The interlayer acts as a cohesive force, holding the glass together even when broken.

The production process involves carefully curving the glass before applying the PVB interlayer and subjecting it to a lamination process. The result is a durable and versatile material suitable for various applications.

Advantages of Curved PVB Laminated Glass

Enhanced Safety and Security

One of the primary benefits of curved PVB laminated glass is its enhanced safety features. In the event of breakage, the glass fragments tend to adhere to the PVB interlayer, minimizing the risk of injury from sharp glass shards. This makes it an ideal choice for areas where safety is paramount, such as in public spaces or automotive applications.

Design Versatility and Aesthetic Appeal

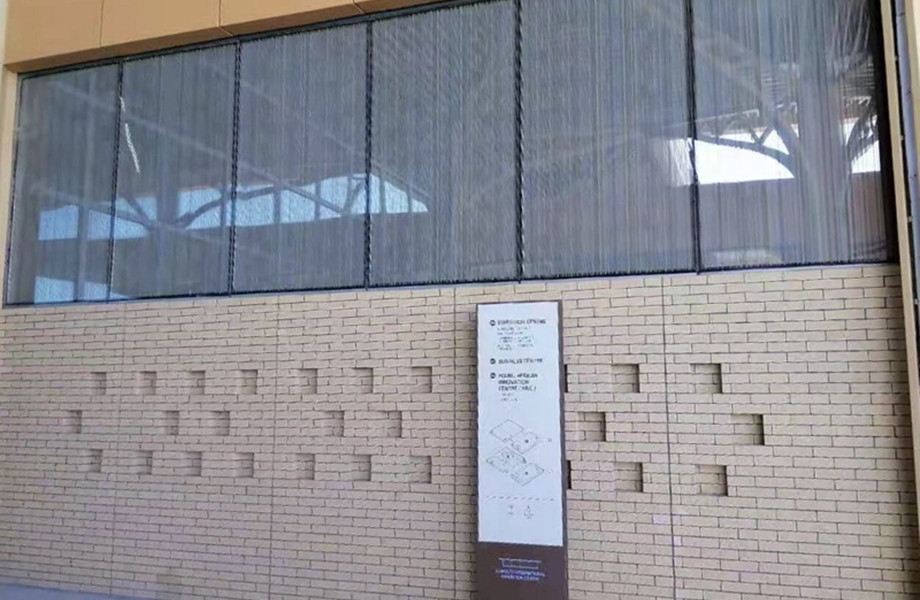

Curved PVB laminated glass offers designers and architects greater flexibility in creating innovative and visually striking structures. The ability to curve glass opens up possibilities for unique and creative designs in both interior and exterior applications. From curved facades to elegant glass staircases, this material can transform architectural visions into reality.

Applications of Curved PVB Laminated Glass

Architectural Applications

Curved PVB laminated glass is extensively used in architectural projects to achieve stunning curved glass facades, canopies, and skylights. Its ability to bend and conform to custom shapes allows architects to explore new design concepts and create distinctive buildings that stand out.

Automotive Industry Usage

In the automotive industry, curved PVB laminated glass plays a crucial role in vehicle design and safety. It is used for windshields and side windows, offering improved impact resistance and reducing the risk of ejection during accidents. The curved glass also enhances the aesthetics of vehicles, contributing to a sleek and modern appearance.

Technical and Performance Aspects

Thermal and Solar Performance

Curved PVB laminated glass can be optimized for thermal and solar performance by incorporating low-emissivity coatings and other advanced technologies. This helps improve energy efficiency by reducing heat gain and loss through windows, contributing to sustainable building designs.

Acoustic Properties

The use of PVB interlayers in curved laminated glass also provides acoustic benefits by damping sound transmission. This makes it an ideal choice for projects where noise control is essential, such as in urban environments or buildings located near busy roads.

Environmental and Sustainable Aspects

Eco-Friendly Attributes

Curved PVB laminated glass can contribute to sustainable building practices due to its durability and longevity. By enhancing the thermal performance of buildings, it can reduce energy consumption for heating and cooling, ultimately lowering carbon emissions.

Longevity and Durability

With proper maintenance, curved PVB laminated glass can have a long service life, reducing the need for frequent replacements and minimizing waste. Its durability makes it a sustainable choice for architectural and automotive applications, supporting environmental conservation efforts.

Conclusion

Curved PVB laminated glass offers a compelling combination of safety, design versatility, and performance benefits. Its applications range from architectural masterpieces to innovative automotive designs, contributing to safer, more aesthetically pleasing environments.

By understanding its advantages and technical aspects, designers and architects can leverage the potential of curved PVB laminated glass to create sustainable and visually impactful projects.

.jpeg)

5935.jpg)

0610.png)

4590.png)

0482.png)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.jpg)

.jpg)