Heat-Tested Ultra Clear Glass for Skylights Product Description

Our heat-tested ultra clear glass delivers unmatched clarity for skylights. As premium heat soaked low-iron glass, it ensures 99.8% light transmission. Perfect for heat-tested glass skylights in luxury projects.

Specially engineered heat-tested ultra clear glass exceeds skylight standards. This heat soaked low-iron glass resists thermal stress, making heat-tested glass skylights 30% more durable than conventional options.

Product Specifications

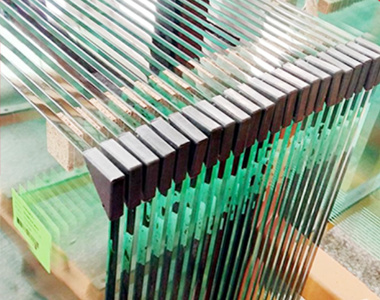

Heat Soaking Test Processing

| Product Name | Heat soak test tempered glass |

| Thickness | 4mm,5mm,6mm,8mm,10mm,12mm,15mm,19mm,22mm |

| Max size | 2440*15000mm;1300*3300mm |

| Min size | 100*300mm |

| Quality standard | BS/EN 14179 |

Things to Consider:

Heat soak treatment demands tempered glass.

Cutting or drilling toughened glass is not allowed.

Used across guardrails, bathrooms, interior partitions, curtain walls and more.

KXGlass Business Introduction

Production Process

Float Glass

Cutting

Grinding And Polish

Tempered

Heat soak test

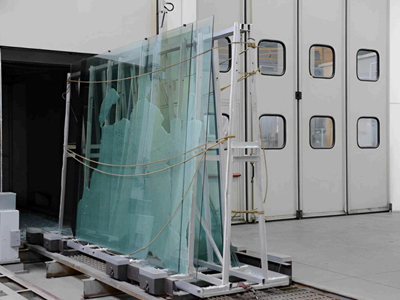

Packaging & Shipping Arrangenents

Separate every individual piece of glass by means of a cork mat.

Appropriate for shipping and land transport, the strong export wooden/plywood crates are ready for use.

An iron belt or belts crafted from other substances are suitable for the process of consolidation.

Each of the four corners of the glass will be fitted with a protective corner.

There is desiccant contained within each box.

Cork Mat And Protective Corners

Soft Rubber Mat

Desiccant

Plywood crates

Support After Product Purchase:

Expedited - response quotation; make a reply within 12 - hour time frame

Technical support, design along with installation pointers

Inspect order details, double - check for accuracy and confirm

Follow your order throughout and update you promptly

Inspection standards & QC reports based on your order

Transmit production, packing, and loading photos without delay at your request

Take charge of transportation and send all docs on time

FAQ

1. Nature of the company?

Based at No. 10 Jinchuan 1st Road, Jinchuan, Zhaolin, Dongguan, Guangdong, we're a glass - processing factory.

2.Do the company's products feature an international third - party independent testing certificate?

Our glass is certified to ANSI, CE, AS/NZS, CCC, etc.

3. The production time of the product in large quantities:

Usually 10-15 days, depending on the order quantity, we can support urgent orders.

4.What's the MOQ?

MOQ is 100 square meter.

5.Do you provide free samples?

Yes, welcome to contact us to discuss your project together.

6. Whether the product itself supports OEM customization?

Yes.

7.How is the warranty?

Yes, generally, we offer 5 years warranty for processing glass based on your normally uses, we advise you uses in a right way can keep your products service life in a long time (more than 5 years).

8.How to get a quotation?

We need the information of Glass types, thickness, sizes, quantity and processing requirements etc.