Product Description

● The heat soak tempered glass door system demonstrates superior safety characteristics, particularly when applied in critical public infrastructure like Subway Screen Doors. Through specialized high-temperature treatment, the tempered glass achieves remarkable strength and impact resistance, maintaining structural integrity even under significant external forces.

● For Subway Screen Doors, building entrances, and safety partitions, heat soak tempered glass doors deliver:

√ Maximum safety with minimized breakage risks

√ Long-term durability for high-traffic applications

√ Compliance with international safety standards

These safety-enhanced tempered glass products have become the standard for modern Subway Screen Doors, offering passengers unparalleled protection. The heat soak tempered glass door technology represents a significant advancement in public transportation safety systems, combining rigorous material testing with robust engineering design.

Product Specifications

| Product Name | Safety Heat Soak Test Tempered Glass for Subway Screen Door |

| Thickness | 5mm,6mm,8mm,10mm,12mm,15mm,19mm |

| Max size | 2440*15000mm;1300*3300mm |

| Min size | 100*300mm |

| Quality standard | BS/EN 14179 |

| Corner | Shape Corner,polished radius,dubbed corner,etc. |

| Edge | Polished /pencil /flat edge,etc |

Process Specifications:

Heat soak testing can only be performed on properly tempered glass

Glass must undergo complete tempering before the soak test

Widely used in subway screen doors, windows, doors, facades, partition walls, curtain walls, etc.

KXGlass Business Introduction

Production Process

Float Glass

Cutting

Grinding And Polish

Tempered

Heat soak test

Package & Shipping

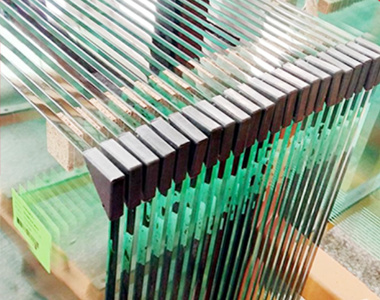

Each glass panel is individually separated using cushioning cork mats.

Sturdy export-grade wooden/plywood crates designed for secure shipping via all transport methods (sea/land/air).

Metal strapping (iron or alternative alloy) secures each crate for transit stability.

All glass edges feature durable protective corner guards for impact resistance

Every crate includes desiccant packs to prevent condensation damage

Cork Mat And Protective Corners

Soft Rubber Mat

Desiccant

Plywood crates

After-sales Service:

● Receive a customized quote within 12 hours of your inquiry

● Professional design consultation and installation guidance

● Thorough review and confirmation of all order specifications

● Continuous updates throughout the production process

● Strict inspection protocols with detailed QC reports

● On-demand photo updates (production, packaging, loading)

● Comprehensive shipping assistance and timely document delivery

FAQ

1. Nature of the company?

We are a glass processing factory located at No. 10 Jinchuan 1st Road, Jinchuan, Zhao Lin, Dongguan City, Guangdong.

2.Does your company’s glass products hold international third-party certifications?

Yes, our glass complies with ANSI, CE, AS/NZS, CCC, and other globally recognized standards.

3. The production time of the product in large quantities:

Usually 10-15 days, depending on the order quantity, we can support urgent orders.

4.What's the MOQ?

MOQ is 100 square meter.

5.Do you provide free samples?

Yes, welcome to contact us to discuss your project together.

6. Whether the product itself supports OEM customization?

Yes.

7.How is the warranty?

We guarantee a five-year warranty for processed glass products under standard use. Proper usage extends lifespan beyond 5 years.

8.How to get a quotation?

We need the information of Glass types, thickness, sizes, quantity and processing requirements etc.