Product Description

● The homogenization treatment process ensures that heat toughened glass partitions achieve superior performance by eliminating impurities and significantly reducing spontaneous breakage risks. This advanced treatment makes safety building glass (BS/EN standard glass) products exceptionally reliable for architectural applications while maintaining excellent optical clarity.

Particularly in door/window systems and heat toughened glass partitions, this treated glass offers:

● Improved safety (meeting BS/EN standard glass requirements)

● Enhanced structural stability

● Maintained aesthetic quality

● All safety building glass products undergo this process to guarantee they exceed BS/EN standard glass (safety building glass) specifications for impact resistance and thermal performance. The result is heat toughened glass partitions that combine safety, durability and design flexibility.

Product Specifications

| Product Name | Heat Soak Test Glass Window Door |

| Thickness | 4mm,5mm,6mm,8mm,10mm,12mm,15mm,19mm |

| Max size | 2440*15000mm;1300*3300mm |

| Min size | 100*300mm |

| Quality standard | BS/EN 14179 |

| Corner | Shape Corner,polished radius,dubbed corner,etc. |

| Edge | Polished edge,pencil edge,flat edge,etc |

Material Requirements:

Only pre-tempered glass qualifies for heat soak processing

The treatment is exclusively applicable to fully toughened glass panels

Heat toughened glass (safety building glass) Widely used in windows, doors, facades, partition walls, curtain walls, etc.

KXGlass Business Introduction

Production Process

Float Glass

Cutting

Grinding And Polish

Tempered

Heat soak test

Package & Shipping

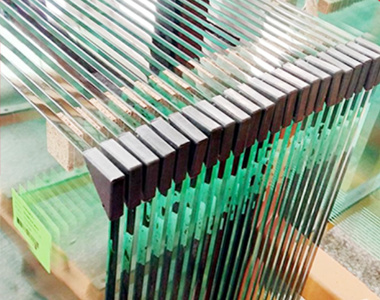

Secure each glass panel with a cork spacer mat.

Durable export-grade wooden/plywood crates, designed for safe shipping and land transportation.

Reinforced with iron or alternative material strapping.

Protective corner guards on all four edges of the glass.

Includes desiccant in every crate for moisture cont

Cork Mat And Protective Corners

Soft Rubber Mat

Desiccant

Plywood crates

After-sales Service:

● Quick quote, reply requirements within 12 hours

● Technical support, design and installation suggestions

● Review your order details, double check and confirm your order without problems

● Entire process follow your order and update you in time

● Quality inspection standard and QC report according to your order

● Production photos, packing photos, loading photos sent in time if you need

● Assist or arrange the transportation and sent you all documents on time

FAQ

1. Nature of the company?

We are a glass processing factory located at No. 10 Jinchuan 1st Road, Jinchuan, Zhao Lin, Dongguan City, Guangdong.

2.Whether the company's products have international third-party independent testing certificate?

Our glass is certified to ANSI, CE, AS/NZS, CCC, etc.

3. The production time of the product in large quantities:

Usually 10-15 days, depending on the order quantity, we can support urgent orders.

4.What's the MOQ?

MOQ is 100 square meter.

5.Do you provide free samples?

Yes, welcome to contact us to discuss your project together.

6. Whether the product itself supports OEM customization?

Yes.

7.How is the warranty?

Yes, generally, we offer 5 years warranty for processing glass based on your normally uses, we advise you uses in a right way can keep your products service life in a long time (more than 5 years).

8.How to get a quotation?

We need the information of Glass types, thickness, sizes, quantity and processing requirements etc.