Breakage-Resistant Heat-Soaked Safety Glass Facade Product Description

Product Specifications

| Product Name | Breakage-Resistant Heat-Soaked Safety Glass Facade |

| Thickness | 4mm,5mm,6mm,8mm,10mm,12mm,15mm,19mm,22mm |

| Max size | 2440*15000mm;1300*3300mm |

| Min size | 100*300mm |

| Quality standard | BS/EN 14179 |

Greatly used in guardrails, bathrooms, interior partitions, curtain walls and more.

KXGlass Business Introduction

Production Process

Float Glass

Cutting

Grinding And Polish

Tempered

Heat soak test

Packing & Carriage

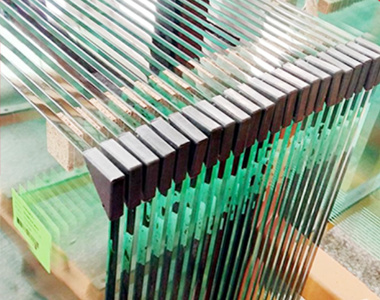

Put a cork mat between the individual pieces of glass for separation.

Appropriate for shipping via sea and transport over land, strong export wooden/plywood crates stand out.

For the purpose of consolidation, an iron belt or belts of different materials may be employed.

The four corners of the glass will be surrounded by protective corners.

Every box contains a portion of desiccant.

Cork Mat And Protective Corners

Soft Rubber Mat

Desiccant

Plywood crates

After-sales Help:

● Produce a speedy quote and respond to the requirements within 12 hours

● Technical support provisions, design formations, and installation recommendations

● Analyze comprehensively your order information, re-check everything, and confirm that your order is proper.

● The whole progression of the process will conform to your order and update you promptly

According to the terms of your order, the quality inspection standards and QC report will be arranged

● Should you have the need, we'll send production snapshots, packing snapshots, and loading snapshots in a timely manner

● We can assist with the transportation arrangements and deliver all the documents to you in a timely manner

FAQ

1. Nature of the company?

Situated at No. 10 Jinchuan 1st Road, Jinchuan, Zhao Lin, Dongguan City, Guangdong, we are a glass processing factory.

2.Is there evidence of an international third-party independent testing certificate for the company's products?

Our glass meets the requirements of ANSI, CE, AS/NZS, CCC, and other certification standards.

3. The time consumed in producing the product in large quantities:

Generally speaking, it requires 10 - 15 days. The time is contingent upon the order quantity. We can meet urgent order needs.

4.What's the MOQ?

MOQ is 100 square meter.

5.Do you provide free samples?

Yes, welcome to contact us to discuss your project together.

6. Whether the product itself supports OEM customization?

Yes.

7.How is the warranty?

Yes, in general, we stand behind our processed glass with a 5 - year warranty for regular use. We advise using it in the right manner to ensure that your products enjoy an extended service life, lasting more than 5 years.

8.How to get a quotation?

It is essential for us to have the information about glass types, the thicknesses involved, the various sizes, the quantity, and the processing demands, etc.