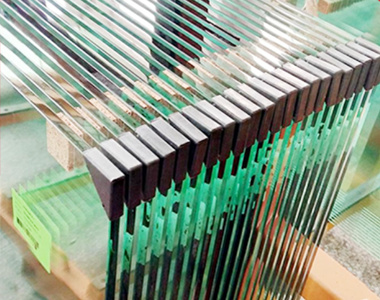

Product Description

Hot bending glass is formed by heating flat glass in a mold to 580–600°C. This technique is ideal for creating dining table glass with seamless curves, as well as special shape glass that can bend via gravity or mechanical assistance to achieve intricate designs. The process allows both dining table glass and special shape glass to adopt unique contours - from organic waves for tabletops to geometric angles for artistic installations - while maintaining structural integrity. Whether producing hot bending glass for architectural features, custom dining table glass, or avant-garde special shape glass, these methods offer unparalleled precision and design versatility.

Product Specifications

| Glass Name | Hot Bending Glass for Dining Table Glass |

| Glass Thickness | 4/5/6/8/10/12/15/19/25mm |

| Size | Customer customized |

| Edge work | Straight edge, beveled edge, round edge etc. |

| Deep Processing | Hole, cutting out, safety corner |

| KXG MOQ | 100sqm |

| Packing | Strong plywood crate with steel belt. |

| Delivery Time | 7-15days after receive the deposit |

| Glass option | Clear, ultra clear glass, tinted glass etc. |

| hot bending glass can produce hollow, sandwich and other composite hot bending glass products, can be tailored to customer requirements. | |

Ideal for diverse applications: fish tanks, dining table glass, balconies, phone/cosmetic counters, TV cabinets, doors, windows, ceilings, and custom-shaped curtain walls.

KXGlass Business Introduction

Production Process

Float Glass

Cutting

Grinding And Polish

Tempering

Package & Shipping

1.Separate each piece of glass with a cork mat.

2.Suitable for shipping and land transport strong export wooden /plywood crates.

3.Iron belt or another material belt for consolidation.

4.The four corners of the glass will have protective corners.

5.Each box contains desiccant.

Customize fumigation-free sealed wooden boxes according to your quantity and size, and take specific inner packaging protection measures to ensure safety during various transportation.

Dust free

Soft Rubber Mat

Desiccant

Plywood crates

After-sales Service

Rapid Quotation Service

Receive a customized quote within 12 hours of your inquiry

Expert Technical Support

Professional design consultation and installation guidance

Order Verification

Thorough review and confirmation of all order specifications

Real-Time Order Tracking

Continuous updates throughout the production process

Quality Assurance

Strict inspection protocols with detailed QC reports

Production Transparency

On-demand photo updates (production, packaging, loading)

Logistics Support

Comprehensive shipping assistance and timely document delivery

FAQ

1. Nature of the company?

We are a glass processing factory located at No. 10 Jinchuan 1st Road, Jinchuan, Zhao Lin, Dongguan City, Guangdong.

2.Whether the company's products have international third-party independent testing certificate?

Our glass is certified to ANSI, CE, AS/NZS, CCC, etc.

3. The production time of the product in large quantities:

Usually 10-15 days, depending on the order quantity, we can support urgent orders.

4.What's the MOQ?

MOQ is 100 square meter.

5.Do you provide free samples?

Yes, welcome to contact us to discuss your project together.

6. Whether the product itself supports OEM customization?

Yes.

7.How is the warranty?

Yes, generally, we offer 5 years warranty for processing glass based on your normally uses, we advise you uses in a right way can keep your products service life in a long time (more than 5 years).

8.How to get a quotation?

We need the information of Glass types, thickness, sizes, quantity and processing requirements etc.