Product Description

Hot Bent Glass Production Process (with Hot Bending Technology)

In hot bent glass production, manufacturers utilize specialized molds and hot bending technology to shape the glass into curved glass forms. Both the glass and mold are heated to 580-600°C during the hot bending process, enabling the material to smoothly adopt precise curved glass contours. This method ensures high accuracy for architectural applications, where curved glass elements like balustrades or atrium enclosures require seamless integration of thermal bending precision and structural stability.

The hot bending operation can proceed via two methods:

1.Gravity-based hot bending (for gentle curves)

2.Mechanically-assisted hot bending (using presses for complex shapes)

After hot bending, the glass undergoes controlled cooling to eliminate residual stresses. This hot bending technology achieves:

Tight radii (up to 150mm)

Non-cylindrical geometries

Custom architectural profiles

Product Specifications

| Glass Name | Custom 10mm 12mm hot bent glass curved glass |

| Glass Thickness | 4/5/6/8/10/12/15/19/25mm |

| Size | Customer customized |

| Edge work | Straight edge, beveled edge, round edge etc. |

| Deep Processing | Hole, cutting out, safety corner |

| KXG MOQ | 100sqm |

| Packing | Strong plywood crate with steel belt. |

| Delivery Time | 7-15days after receive the deposit |

| Glass option | Clear, ultra clear glass, tinted glass etc. |

| Application | Curved glass widely used in aquariums, counters, curtain walls etc. |

Applications

KXGlass Business Introduction

Production Process

Float Glass

Cutting

Grinding And Polish

Tempering

Package & Shipping

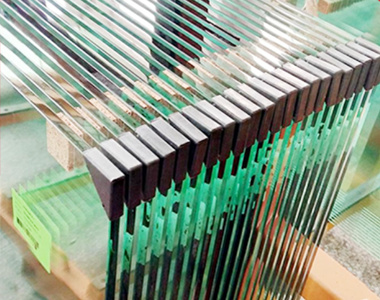

Each glass panel is individually separated using cushioning cork mats.

Sturdy export-grade wooden/plywood crates designed for secure shipping via all transport methods (sea/land/air).

Metal strapping (iron or alternative alloy) secures each crate for transit stability.

All glass edges feature durable protective corner guards for impact resistance.

Every crate includes desiccant packs to prevent condensation damage.

Dust free

Soft Rubber Mat

Desiccant

Plywood crates

After-sales Service:

12-hour quotation – Custom pricing with material breakdown.

Design support – Professional installation guides included.

Triple spec check – Draft, sample, final doc approval.

Live production tracking – Daily progress updates.

7-step QC – X-ray tests, stress analysis, impact reports.

On-demand updates – Photos at cutting, lamination, shipping.

End-to-end logistics – Customs docs, shipping recommendations.

FAQ

1.Who is KXG Industries?

KXG Industries is a leading Chinese manufacturer specializing in precision glass processing and fabrication, serving global architectural and industrial markets with innovative glazing solutions.

2.How long is your delivery time?

Generally within 3 -4weeks.

3.What's the MOQ?

MOQ is 100 square meter.

4.How about sample fees?

Samples are free, can be ready in 1-2 weeks.

5.How is the warranty?

Five years warranty for Laminated Glass, and 10 years warranty for Tempered Glass, Insulated Glass, Windows & Doors and Curtain Wall etc.

6.How to get a quotation?

We need the information of glass composition, thickness, sizes, quantity and processing etc.