Product Description

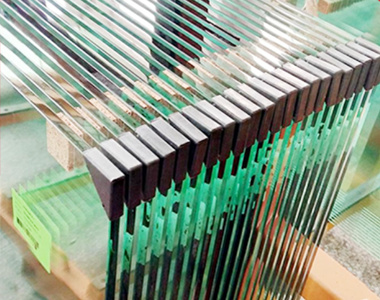

The float glass production process begins by feeding molten glass paste through a controlled gate into a bath of molten tin. Under the combined forces of gravity and surface tension, the glass naturally floats and spreads across the tin surface, forming an exceptionally smooth and uniform sheet. As the glass ribbon moves into the cooling chamber, it solidifies with parallel surfaces free of distortions or waves.

This advanced manufacturing method produces two premium variants:

Clear ultra clear float glass - Achieves exceptional optical clarity with minimal impurities, offering over 91% light transmittance for crystal-clear applications.

Colored float glass - Incorporates metal oxide additives during production to create consistent, vibrant tints while maintaining the flawless surface quality characteristic of float glass.

Both clear ultra clear float glass and colored float glass benefit from the precision of the float process, ensuring:

Perfectly flat, distortion-free surfaces

Uniform thickness throughout the sheet

Excellent light transmission (for clear variants) or consistent coloration (for tinted versions)

The clear ultra clear float glass is particularly valued in high-end architectural and display applications where optical purity is critical, while colored float glass serves both aesthetic and functional purposes in solar control and design-focused installations.

Product Specifications

| Glass Name | Customized modern design clear and ultra clear float tinted glass factory |

| Glass Thickness | 4/5/6/8/10/12/15/19mm |

| Size | Customer customized |

| Edge work: | Straight edge , beveled edge, round edge etc. |

| Deep Processing | Hole, cutting out, safety corner |

| KXG MOQ | 100sqm |

| Packing | Strong plywood crate with steel belt. |

| Delivery Time | 7-15days after receive the deposit. |

| Glass option | Clear, ultra clear glass, grey, bronze etc. |

| Application | Widely used in shower door, partition wall, hotel and home etc. |

Application

KXGlass Business Introduction

Production Process

Float Glass

Cutting

Grinding And Polish

Tempering

Package & Shipping

Separate each piece of glass with a cork mat.

Suitable for shipping and land transport strong export wooden /plywood crates.

Iron belt or another material belt for consolidation.

The four corners of the glass will have protective corners.

Each box contains desiccant.

Kraft paper spacing

Soft Rubber Mat

Desiccant

Plywood crates

After-sales Service:

Quick quote, reply requirements within 12 hours

Technical support, design and installation suggestions

Review your order details, double check and confirm your order without problems

Entire process follow your order and update you in time

Quality inspection standard and QC report according to your order

Production photos, packing photos, loading photos sent in time if you need

Assist or arrange the transportation and sent you all documents on time

FAQ

1.Who is KXG Industries?

KXG Industries is professional glass manufacturer, is a reputable glass deep-processing corporation in China.

2.How long is your delivery time?

Generally within 3 -4weeks.

3.What's the MOQ?

MOQ is 100 square meter.

4.How about sample fees?

Samples are free, can be ready in 1-2 weeks.

5.How is the warranty?

Five years warranty for Laminated Glass, and 10 years warranty for Tempered Glass, Insulated Glass, Windows & Doors and Curtain Wall etc.

6.How to get a quotation?

We need the information of glass composition, thickness, sizes, quantity and processing etc.