Product Description

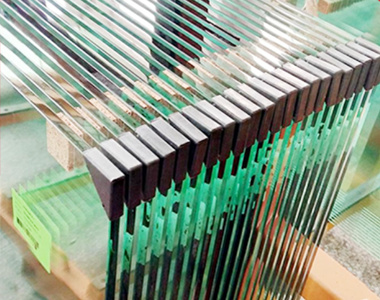

● The advanced PET film printing process creates stunning security laminated glass by sandwiching digitally printed films between glass layers. This technique produces durable, image-carrying security laminated glass that combines artistic design with robust protection.

● PET printing technology revolutionizes architectural glass by enabling customized patterns while maintaining the strength of security laminated glass. Ideal for decorative partitions, façades and safety applications, these laminated panels offer both visual appeal and impact resistance.

● The result is versatile glass products that merge safety standards with unlimited design possibilities through this innovative manufacturing process.

Product Specifications

| Product Name | PET laminated glass |

| Thickness | 3+3/4+4/5+5/6+6/8+8mm |

| PET film | Customer |

| Size | Customer demand |

| Corner | Shape Corner,polished radius,dubbed corner,etc. |

| Edge | Polished edge,pencil edge,flat edge,etc |

Widely used in skylight, office partition, railing, curtain wall, etc.

KXGlass Business Introduction

Production Process

Float Glass

Cutting

Grinding And Polish

Tempered

laminated

Package & Shipping

1.Anti-Abrasion Protection

Use cork pads as spacers between glass panels to eliminate friction during transit.

2.Durable Transport Packaging

Pack glass panels in high-grade inspection-free plywood crates, engineered for all-terrain transport durability (sea/road).

3.To further secure wooden boxes, metal straps or other materials are used to reinforce the structure.

4.To prevent damage to the corners of the glass, protective corners are placed on all four corners of each glass pane.

5.A desiccant is placed inside each case, which helps absorb any moisture that may be present, keeping the glass panels dry and free from damage from moisture.

Cork mat and protective corners

Soft Rubber Mat

Desiccant

Plywood crates

After-sales Service:

● Quick quote, reply requirements within 12 hours

● Technical support, design and installation suggestions

● Review your order details, double check and confirm your order without problems

● Entire process follow your order and update you in time

● Quality inspection standard and QC report according to your order

● Production photos, packing photos, loading photos sent in time if you need

● Assist or arrange the transportation and sent you all documents on time

FAQ

1. Nature of the company?

We are a glass processing factory located at No. 10 Jinchuan 1st Road, Jinchuan, Zhao Lin, Dongguan City, Guangdong.

2.Whether the company's products have international third-party independent testing certificate?

Our glass is certified to ANSI, CE, AS/NZS, CCC, etc.

3. How can l get the price?

We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

4. Can l get free samples?

Yes. Please feel free to contact us.

5. What is your lead time?

Lead time varies by order volume and season: 7-15 days for small orders, 30 days for bulk. Flexible scheduling guaranteed.

6. What is the shipping method?

lt could be shipped by sea, by air, or by express(EMS, UPS, DHL, TNT, FEDEX, etc). Please confirm with us before placing orders.

7. How do you make our business long-term and good relationship?

We keep good quality and competitive prices to ensure our customers benefit.